FabHouse

The Fab House, is generally inspired by the tiny house movement and in particular by the Wikihouse and the Earthships, which favors not only environmentally friendly and affordable living but also a natural life and democratic house building.

FabHouse was made in a interdisciplinary course at Rhine-Waal University of Applied Sciences in winter term 2017-2018. We developed an open source self-sufficient house that can be reproduced in any of the >1400 Fab Labs worldwide and be deployed anywhere in the world. This vision is taken from the WikiHouse-Project, which “endeavors to democratize and simplify the construction of sustainable, resource-light dwellings“. However, the focus of this course was to not to simply copy it but to ‘Re-Think it’, driven by the goal of making it as sustainable as possible. This included not only the construction of the house and materials used, but also energy harvesting and management systems.

Build something big!

We aim to integrate the FabLab as an integral part of almost all of our study programs. It is used as a shared work and teaching-place to bring students and industry together. The interdisciplinary character of the project encourages students to discover new topics and gather practical experiences in different fields. Within the scope of the course, we were faced with students of different backgrounds (computer science, environmental sciences, mobility and logistics, international business sciences). Just very few of the 12 students had prior experience in fabrication and handicrafts. We wanted them to work together and to cooperatively come up with solutions to build a real house. The major focus was not just to make it, but to make it in the most sustainable way.

Eco-Design-Sprint Approach

To create a new mindset of eco-friendly makers, we set up a so called Eco-Design-Sprint approach and applied this within our FabLab.

This approach is based on the idea of Ecodesign (Tischner & Moser, 2015), which leads to solutions that, throughout the entire product lifecycle, optimize performance of desired benefits, minimize negative environmental impacts, or even positively impact the natural environment. In a continuous report-discuss-and-develop-practice, a set of ten of the most common issues that must be addressed in EcoDesign, known as the ‘The 10 Golden Rules’ (Luttropp & Lagerstedt, 2006), have been used as guidance to keep the discussion and development focused on the sustainability of the project.

Eco-design projects involve intense research, more than conventional product design projects. This includes research about materials, technologies and target audiences. This can especially be confirmed for the context in which we applied the framework – a study course that aims to create a sustainable house, made in a fab lab. Because of this context, we also had to tailor the general approach of Ecodesign. The course does not address the typical target audience of product designers (for which the framework was made) nor commercialization (including sales) of the product.

The word ‘Sprint’ refers to the speed in which we applied it. Due to the weekly meetings as part of the course, we established a report-discuss-and-develop-practice.

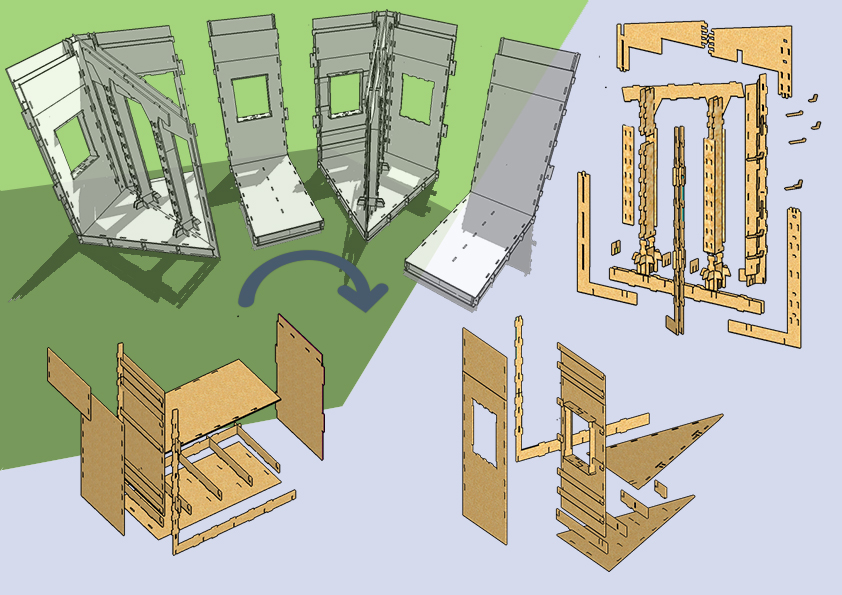

Design of the FabHouse

We worked on growing idea of the structure. The main idea is to give the house a core. This core side size can be varied, but every module is connected to it. The geometry of this structure provides the flexibility to scale the design of the house – it can “grow”. Different kind of composition can be seen in the example figures above. The core serves to maintain the house, such as electrical systems and water systems are embodied to the core.

The FabHouse has an inverted roof shape, inspired by a leaf. It is collecting rainwater in the centre of the leaf – in it’s core. The FabHouse construction system is based on three modules: Middle, corner (“caky”) and key modules. Key modules link all other modules and provide columns to carry the roof. Corner modules can be mirrored. Middle parts are used to stretch the space. All modules are growing around the core.

Assembly

You can download the original files (made with Sketchup) in case you want to change the design of the FabHouse according to your needs.

We also provide you with the cutting files (.dxf) and an assembly manual.

FabHouse Assembly Manual: FabHouse Assembly Manual v1.0

FabHouse Cutting-Files: FabHouse CuttingFiles v1.0.dxf

FabHouse SketchUp: FabHouse SketchUp v1.0.skp

If you have any questions please do not hesitate to contact us: fablab@hochschule-rhein-waal.de

This work is licensed under a CC license: Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Thanks

Special thanks goes to our sponsor, who provided the roofing material for the project:

We would also like to thank all the students who contributed to the realization of our idea. This includes numerous students who were directly or indirectly involved in the project, as well as all employees who supported us.